MD-1000

Ultrasonic-Thermal

Convergence Diagnosis Solution

"One-Click" Condition Assessment Algorithm

Identify equipment defects in noisy environments using Active Ultrasonic Noise Cancelation (AUNC) technology from long distances

Assess the condition of the target equipment in under a minute,

it's quick & easy!

First-Ever Commercialized

Convergence Diagnosis Imager

Ultrasonic-thermal-optical multi-diagnosis algorithm technology

Analog Ultrasonic Sensors

Multiple analog ultrasonic sensors with cone-type receiver provide greater locational accuracy, detection distance, and detects more subtle defects

Active Ultrasonic Noise Cancelation (AUNC)

Blocks external environmental noise and noise in the ultrasonic frequency, simultaneously visualizing and converting ultrasonic signals to audible frequencies

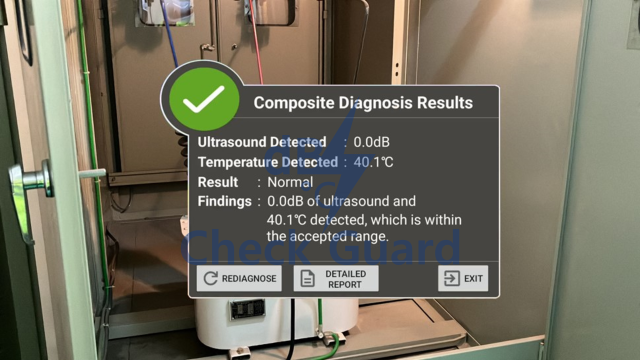

Composite Diagnosis Mode

Overlapping display of ultrasonic and thermal modes helps users detect partial discharge, gas leaks, and thermal degradation concurrently

Composite Analysis (ANLYZ)

Condition assessment of the target equipment and detailed diagnostic report provided via cross-analysis of heterogeneous data, all within a minute

"One-Click" Condition Assessment

Self-developed by EntecPower based on collected big data of over 1.5 million defect diagnoses of power equipment

MD-1000, the ultimate tool

The MD-1000 is the only equipment you need on-site to detect partial discharge (PD), gas leaks, and thermal degradation. The equipped AUNC technology blocks unwanted environmental noise to help you accurately detect defects in both power and gas equipment.

High-Voltage Power Equipment

Partial discharge and thermal degradation detection in transmission, distribution, substation, distribution panel, power plants, and electric railways

Gas, Compressed Air & Steam Equipment

Leak detection in high-pressure gas, compressed air, steam pipe, and storage facilities of chemical, energy, and manufacturing plants (valve/pipeline/tank)

MD-1000 is equipped with ultrasonic, thermal, and composite diagnosis mode

to help users detect various defects in different equipment and facilities

Composite Diagnosis Mode

- Ultrasonic mode with thermal overlay

- Detect both defective ultrasonic signals and thermal degradation

Ultrasonic Mode

- Detect & visualize defective ultrasonic waves

- TIME & FFT graph to help identify and distinguish defects

Thermal Mode

- Detect thermal degradation and leaks using six (6) different thermal palettes

MD-1000 is equipped with convenient and useful features to enhance on-site user experience

SAVE

- Detect thermal degradation and leaks using six (6) different thermal palettes

FREEZE

- One-click screen freezing feature

- Simultaneous screen capture & automated image save (.png)

ANLYZ

- Helps determine the condition of the equipment into: Normal, Caution, or Defect

- Provides suggested follow-up measures

Why MD-1000?

Quick & Easy

Diagnosis completed and detailed report provided, all in under a minute (~10 sec)

Comprehensive Diagnosis

Using just a single imager, one click of a button helps users diagnose and distinguish defects while providing users with reliable, expert-level diagnostics

Reduced Cost/TIme, Increased Efficiency

92% reduction effect (labor, maintenance, time) in comparison to existing single-technology diagnostic equipment, maximizing defect detection

Diagnosis in Noisy Environments

With AUNC technology, PD and gas leak detection is possible in large-scale factories and industrial facilities with extreme noise

Ergonomic Design

MD-1000 is ergonomically designed for comfortable operation by everyone using the jogswitch, action buttons, and/or touchscreen

Competence & Reliability

MD-1000 is the reflection of accumulated know-how and on-site diagnosis experience of over 10 years, including 1.5 million defect diagnoses from 25 million diagnoses of power equipment

Why Composite Diagnosis?

By combining contactless diagnostics and integrating two heterogeneous diagnostic technologies (ultrasonic, thermal), there is no need for multiple devices

Ultrasonic Technology

Detect ultrasonic signals emitted from defective

power and gas facilities

Thermal/Infrared Technology

Detect thermal degradation of defective industrial facilities

Optical Technology

Physical diagnosis of defective power and gas facilities

Composite Analysis Algorithm

Diagnosis of defective facilities, increased detection reliability, with the ultimate goal of 100% defect detection

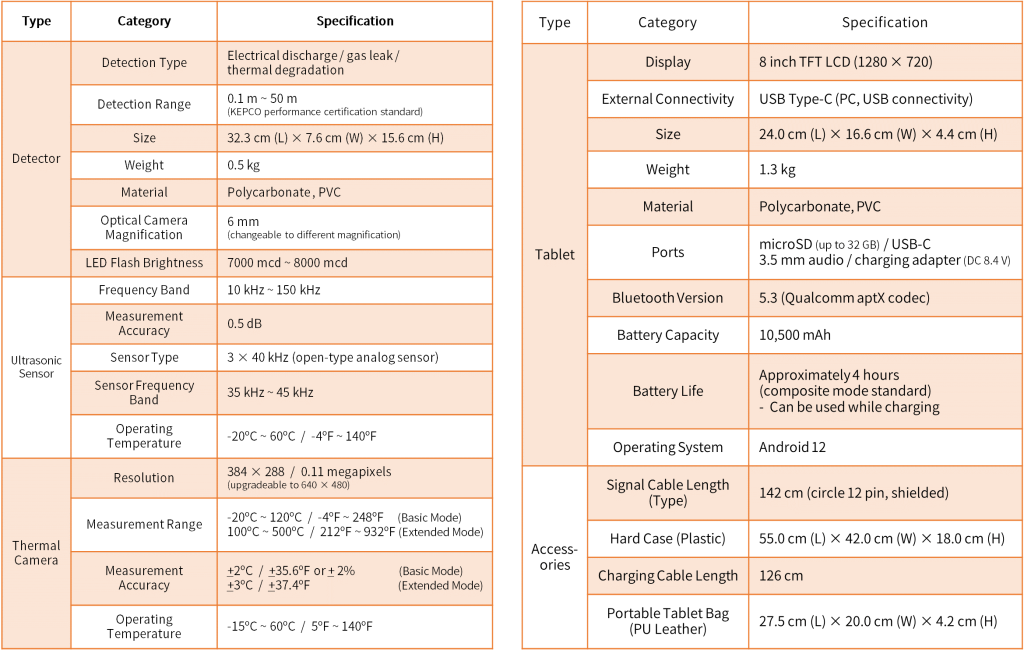

MD-1000 Product Specifications

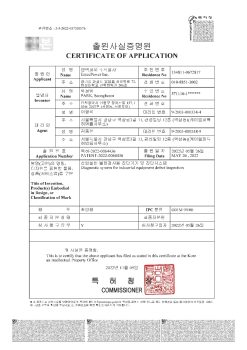

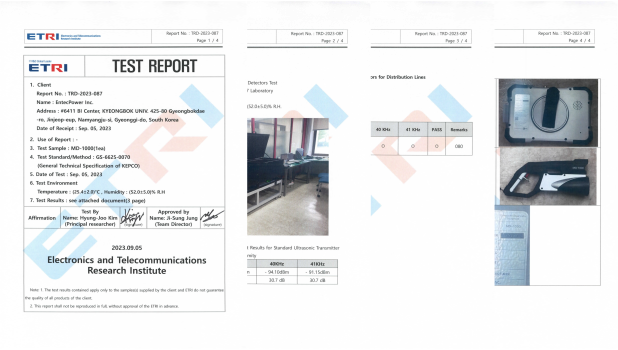

MD-1000 Certifications

Certificate of Patent Application – Convergence Diagnostics

Ultrasonic Diagnostic Equipment Performance Test (KEPCO Standard)

MD-1000 Introduction Video

ENGLISH

한국어

Download Links

The MD-1000 product catalog, user manual, and quick start guide are available for you to download via the links below